Many older homes across North America, especially those built in the 1960s and 1970s, were constructed using aluminum wiring instead of copper. While it was once seen as a cost-effective alternative, aluminum wiring has since proven to pose several safety and performance risks for modern households. Understanding these dangers is crucial for homeowners who want to keep their electrical systems safe and compliant.

Why Aluminum Wiring Can Be Dangerous

1. Fire Hazards

One of the biggest concerns with aluminum wiring is the heightened risk of electrical fires. Aluminum expands and contracts more than copper as temperatures change, which can loosen connections at outlets, switches, and junction boxes. Over time, these loose connections can create resistance, generate excessive heat, and potentially start a fire.

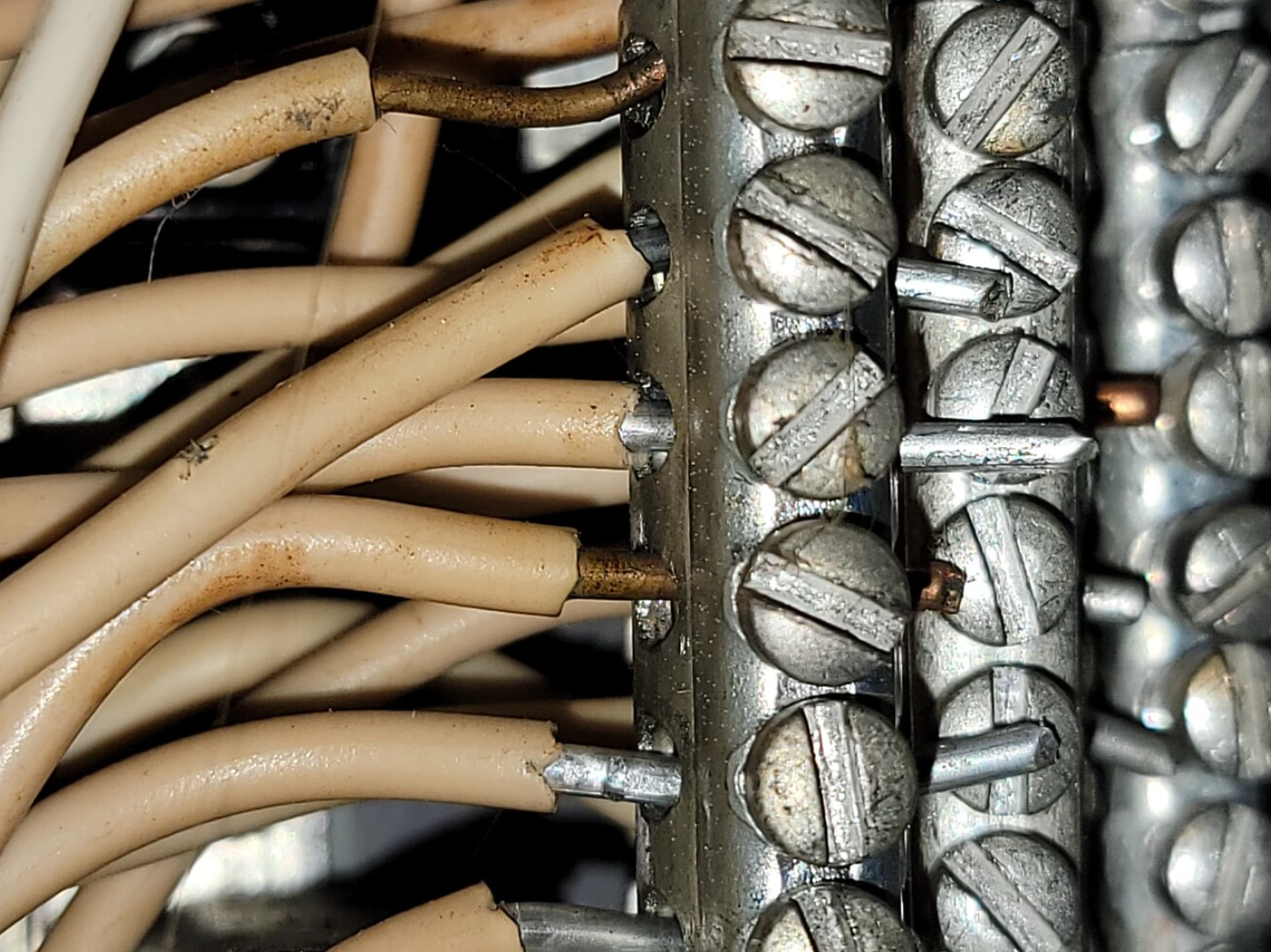

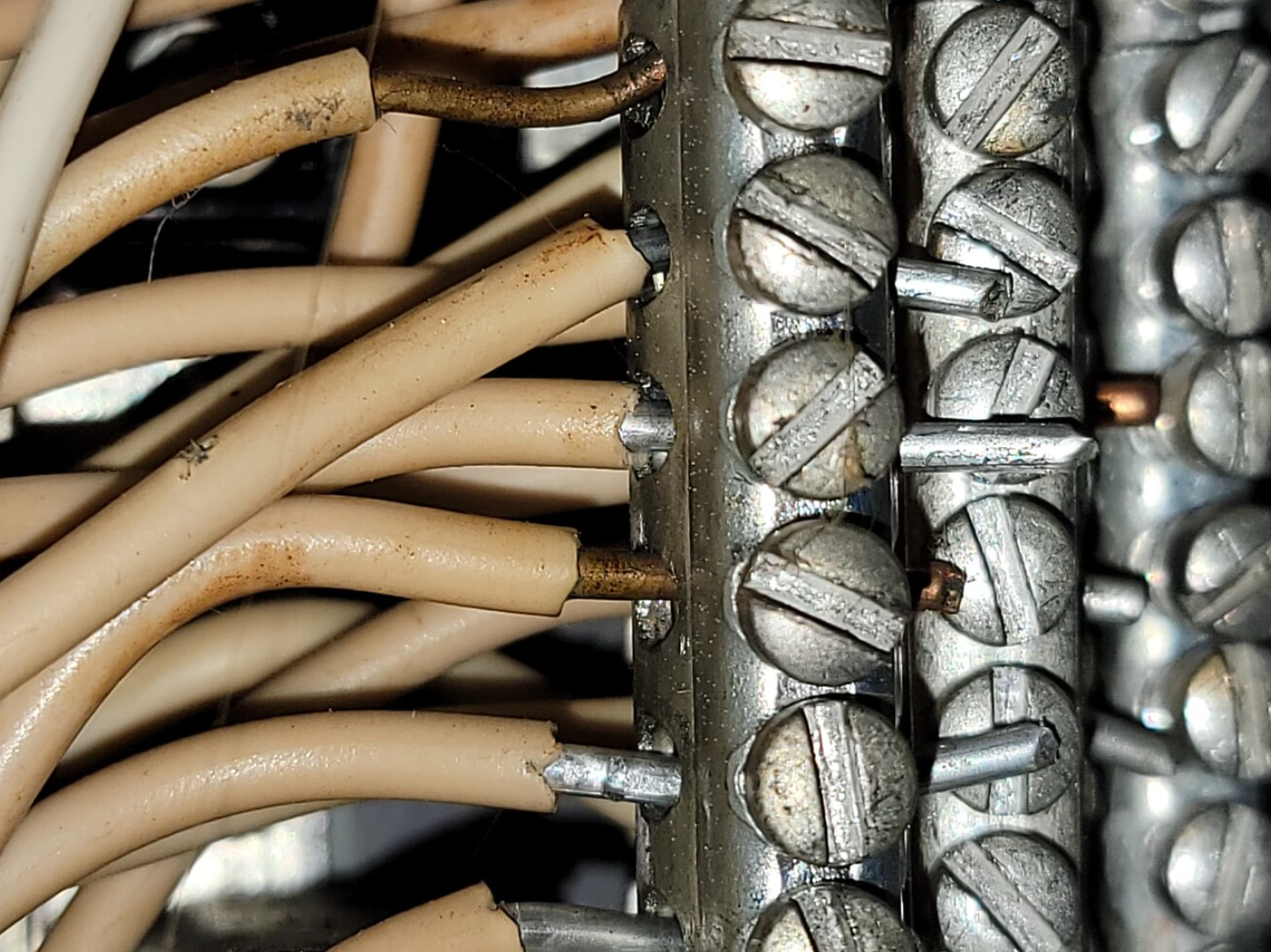

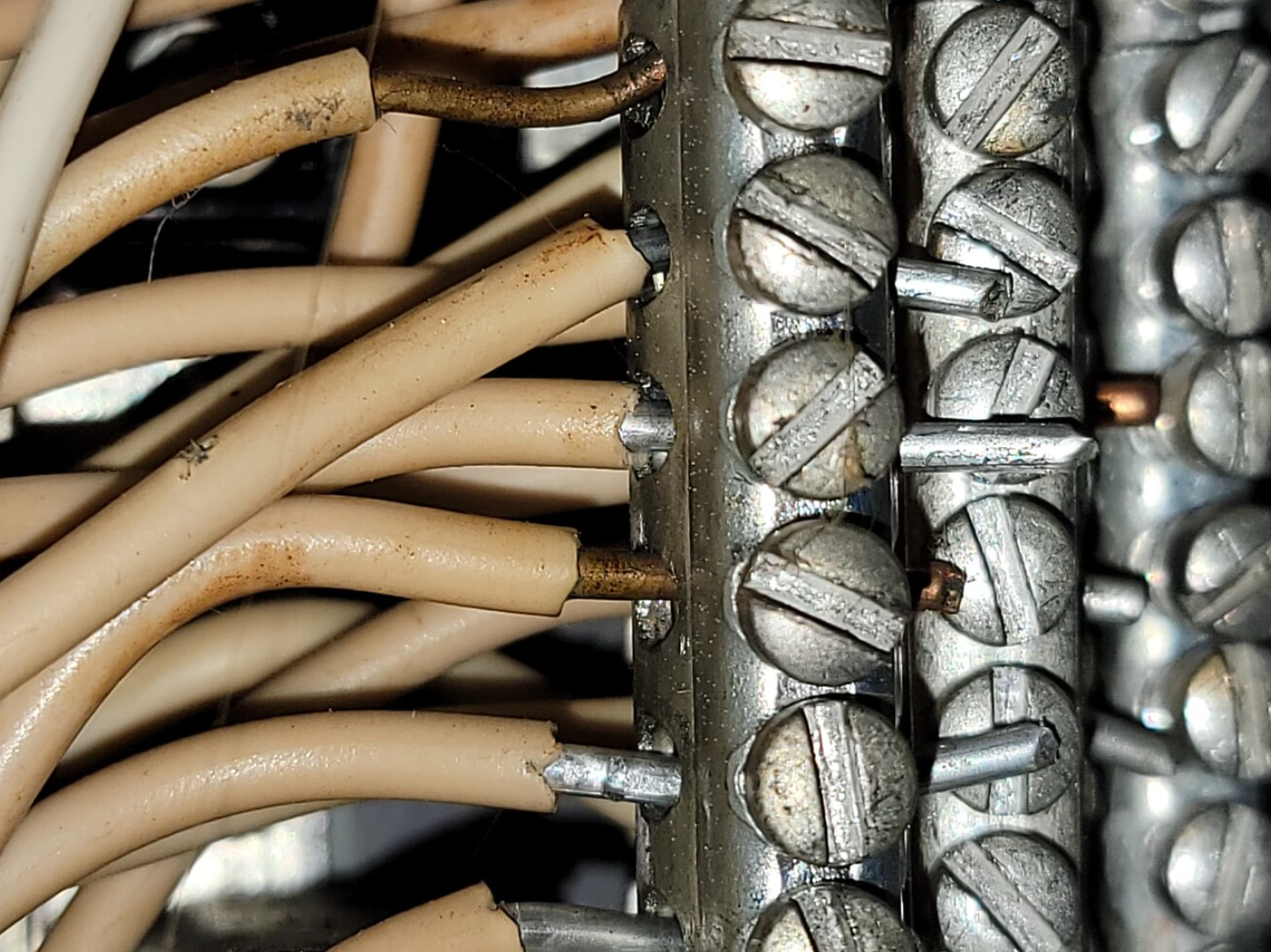

2. Oxidation and Corrosion

Aluminum wiring naturally forms an oxide layer on its surface when exposed to air. This oxidation increases electrical resistance, leading to overheating and potential failure at connection points. Additionally, the oxide coating makes it difficult to spot loose or deteriorating connections during inspections.

3. Compatibility Problems

Aluminum wiring is less compatible with devices and fixtures designed for copper wiring. Because it’s stiffer and more brittle, aluminum wire requires special connectors and terminations to ensure safe and secure electrical contact. Using standard copper-only devices with aluminum wiring can create hazardous conditions.

4. Flickering Lights and Unstable Power

If you notice flickering lights, dimming, or intermittent power in certain outlets, aluminum wiring may be the culprit. These symptoms are often early warning signs of loose connections or overheating circuits that require immediate attention.

5. Expensive Repairs

Correcting problems with aluminum wiring can be costly and time-consuming. Depending on the severity of the issue, the solution might involve specialized connectors, pigtailing, or even complete rewiring. Because these repairs involve safety-critical components, hiring a licensed electrician is essential.

6. Lower Home Value

Homes with aluminum wiring often face reduced resale value. Potential buyers may hesitate due to the perceived fire risk or the expected cost of electrical upgrades. Addressing or replacing aluminum wiring can make your property more attractive and easier to sell.

How to Manage Aluminum Wiring Safely

Regular Inspections

Schedule routine electrical inspections to detect loose connections, discoloration, or other signs of overheating. Preventive maintenance can help minimize risks before they become serious hazards.

Use Proper Connectors

When joining aluminum and copper wiring, always use approved aluminum-to-copper connectors or “pigtails.” These connectors are designed to prevent oxidation and ensure a stable connection between different metals.

Hire a Licensed Electrician

If you suspect problems or notice electrical irregularities, contact a qualified electrician. A professional can evaluate your system and recommend the best corrective measures—whether that’s tightening connections, replacing outlets, or upgrading the wiring entirely.

Consider Rewiring

For long-term peace of mind, some homeowners choose to replace aluminum wiring with copper. Although it’s a more expensive option, it eliminates the root of the problem and enhances overall electrical safety.

Final Thoughts

While aluminum wiring was once a common choice, it poses real safety risks in modern homes. Regular maintenance, proper connectors, and professional inspections can go a long way toward keeping your home safe. Always remember: electrical work should be handled only by certified electricians to meet local building codes and safety standards.

Many older homes across North America, especially those built in the 1960s and 1970s, were constructed using aluminum wiring instead of copper. While it was once seen as a cost-effective alternative, aluminum wiring has since proven to pose several safety and performance risks for modern households. Understanding these dangers is crucial for homeowners who want to keep their electrical systems safe and compliant.

Many older homes across North America, especially those built in the 1960s and 1970s, were constructed using aluminum wiring instead of copper. While it was once seen as a cost-effective alternative, aluminum wiring has since proven to pose several safety and performance risks for modern households. Understanding these dangers is crucial for homeowners who want to keep their electrical systems safe and compliant. Many older homes across North America, especially those built in the 1960s and 1970s, were constructed using aluminum wiring instead of copper. While it was once seen as a cost-effective alternative, aluminum wiring has since proven to pose several safety and performance risks for modern households. Understanding these dangers is crucial for homeowners who want to keep their electrical systems safe and compliant.

Many older homes across North America, especially those built in the 1960s and 1970s, were constructed using aluminum wiring instead of copper. While it was once seen as a cost-effective alternative, aluminum wiring has since proven to pose several safety and performance risks for modern households. Understanding these dangers is crucial for homeowners who want to keep their electrical systems safe and compliant.